Sanitary Pump Seals

Alfa-Laval Seals

APV Seals

Fristam® Seals

Tri-Clover® Seals

Waukesha® Seals

Sanitary Mixer Seals

ZN Sgl Cartridge Seal

ANSI Process Pump Seals

ZA Sgl Cartridge Seal

ZN Sgl Cartridge Seal

ZND Dbl Cartridge Seal

Process Mixer Seals

ZN Sgl Cartridge Seal

Seal Application Sheet

Sanitary PD Pumps

ZD-U1

ZD Evolution

Sanitary Centrifugal Pumps

ZC-10 Series

Tri-Clover® C-Series

ZMT T3EH & T4EH Series

PD Pump Application Sheet

Tri-Clover ® Pump Parts

C-Series

3EH & 4EH-Series

Waukesha® Pump Parts

Model U1

Model U2

5000 Industrial Series

Waukesha® Pump Repair

Model U1

Model U2

5000 Industrial Series

Fillers

Aseptic Fillers

Automated Aseptic Fillers

Piston Fillers

Vacuum Fillers

Sterilizers

Pasteurizers

Robotic Palletizers

Filler Application Data Sheet

|

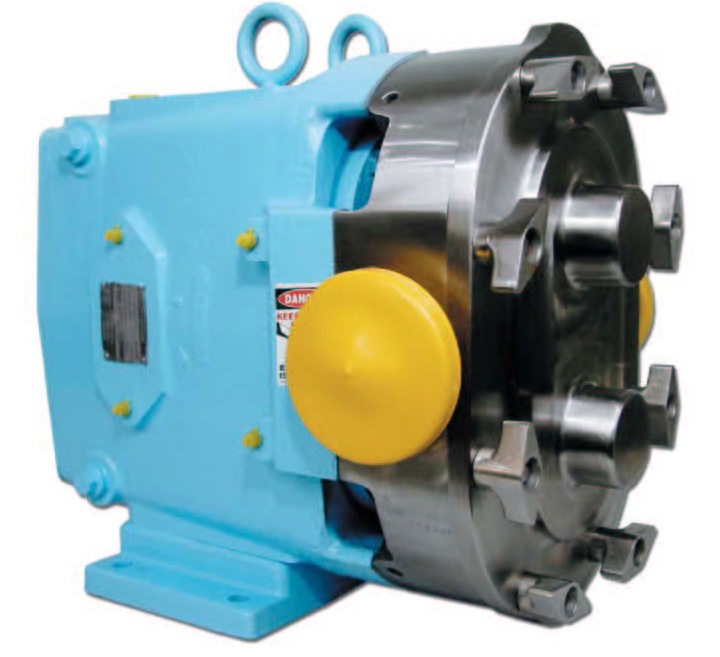

ZM Technologies

remanufactures many different sanitary pumps, like Alfa-Laval, APV, Sine, • Universal I Pumps: Models 006 U1 thru 523 • Universal II Pumps: Models 006 U2 thru 324 U2. • 5000 Series Pumps: 5020. 5030, 5040, 5060, 5080 While the O.E.M offers TWO rebuilds, our custom remanufacturing program rebuilds a pump up to FIVE times, thus saving money over the life of the pump and and reducing the number of new pumps purchased.  Many different rebuild programs are available for your convenience: gearbox. cover All pump rebuilds are quoted before work begins. The customer is always given a choice of the type of rebuild. |

| Oil Bath Conversion - Convert pump gear box to oil lube, instead of grease lube. This improves bearing life, which provides better rotor wear and improved reliabilty. |

|||||||||||

| ZMT Seal Conversion - Convert pump seals to the flushless, more rugged ZMT engineered seal. |

|||||||||||

| Wearbility Upgrade - Convert pump to a hardened body with Z-Alloy rotors for up to 4 times better life . |

|||||||||||

|

|||||||||||

| |

|||||||||||

Fristam®, Tri-Clover®, and Waukesha® are trademarks of their respective companies.

ZMT, Inc. is not a representative, nor affiliated with Alfa-Laval, APV, Fristam®, Tri-Clover®, or Waukesha®./SPX Flow Technology