Sanitary Pump Seals

Alfa-Laval Seals

APV Seals

Fristam® Seals

Tri-Clover® Seals

Waukesha® Seals

Sanitary Mixer Seals

ZN Sgl Cartridge Seal

ANSI Process Pump Seals

ZA Sgl Cartridge Seal

ZN Sgl Cartridge Seal

ZND Dbl Cartridge Seal

Process Mixer Seals

ZN Sgl Cartridge Seal

Seal Application Sheet

Sanitary PD Pumps

ZD-U1

ZD Evolution

Sanitary Centrifugal Pumps

ZC-10 Series

Tri-Clover® C-Series

ZMT T3EH & T4EH Series

PD Pump Application Sheet

Tri-Clover ® Pump Parts

C-Series

3EH & 4EH-Series

Waukesha® Pump Parts

Model U1

Model U2

5000 Industrial Series

Waukesha® Pump Repair

Model U1

Model U2

5000 Industrial Series

Fillers

Aseptic Fillers

Automated Aseptic Fillers

Piston Fillers

Vacuum Fillers

Sterilizers

Pasteurizers

Robotic Palletizers

Filler Application Data Sheet

|

|||||||||||||||||||||||||||||||||

|

| |||||||||||||||||||||||||||||||||

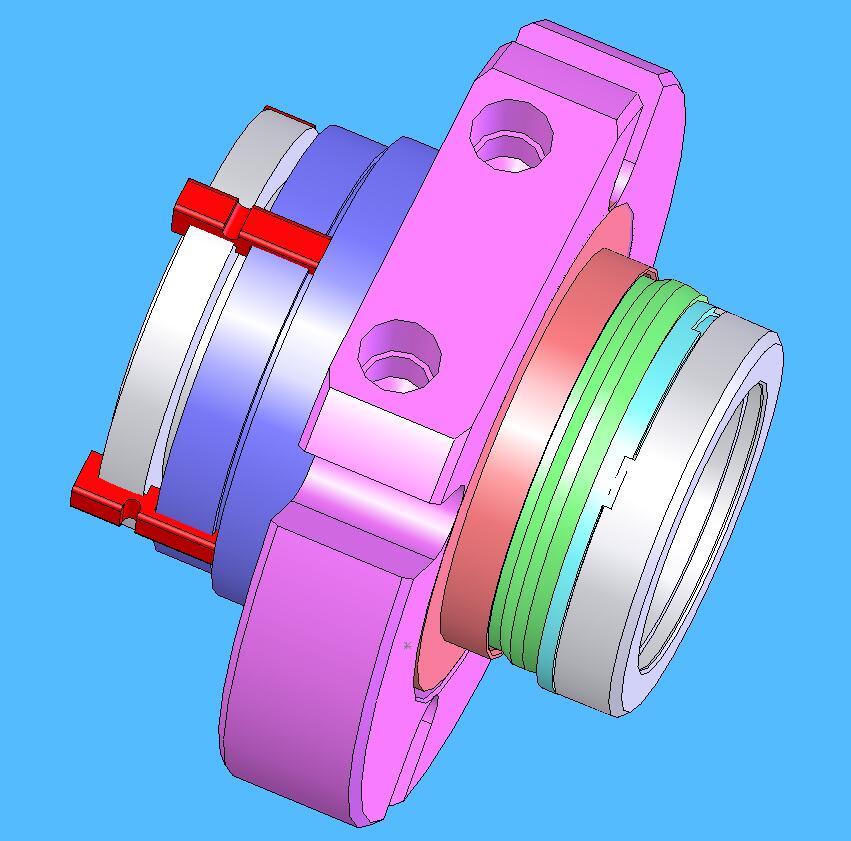

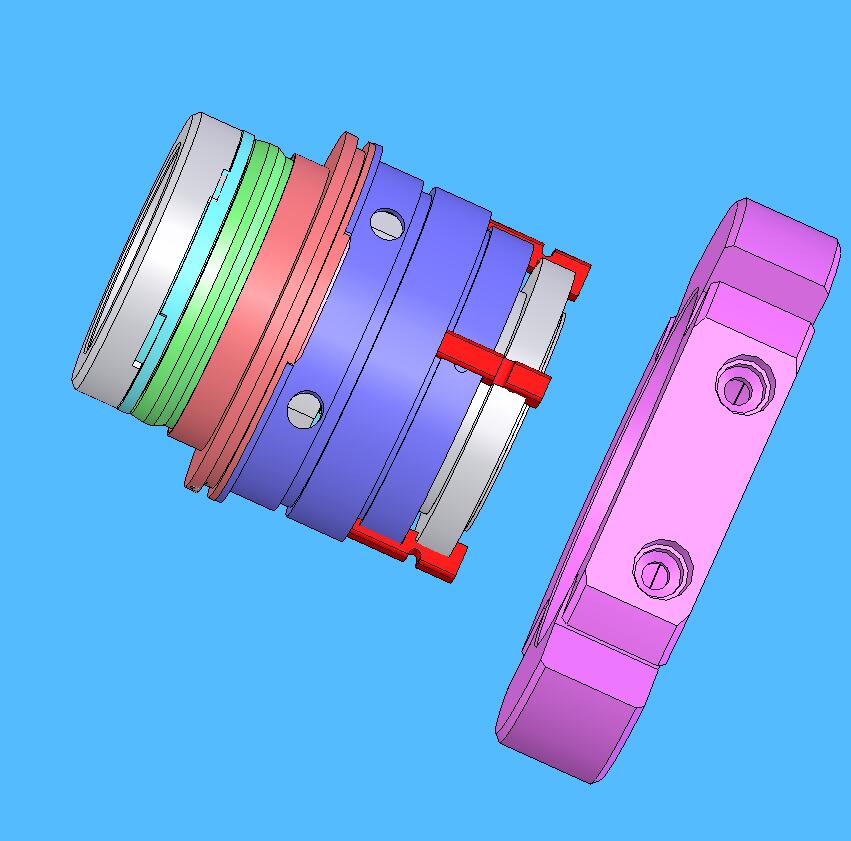

| ZND Pump Seals | |||||||||||||||||||||||||||||||||

|

|

|||||||||||||||||||||||||||||||||

| Bi-directional pumping ring for better cooling and for an ultra-low flush, which dramatically reduces water consumption. |

|||||||||||||||||||||||||||||||||

The least expensive tandem seal on the market. Even priced better than most double seals.| Repair is inexpensive and easy, with the Inner Cartridge. |

Convenient one-side flush connections. |

True tandem design offers full redundancy. Outer seal can operate under full product pressure, up to 400 psi. |

The ZND seal family is designed to operate cooler at higher pressures than the competition, typical operating temperatures are up to 400 deg. F., and up to 400 psi. Consult the factory for the specifics of your application for a recommendation. Remember . . . . . . . Heat Kills.

|

|

| ||||||||||||||||||||||||||||

Fristam®, Tri-Clover®, and Waukesha® are trademarks of their respective companies.

ZMT, Inc. is not a representative, nor affiliated with Alfa-Laval, APV, Fristam®, Tri-Clover®, or Waukesha®./SPX Flow Technology

The ZMT ZND double/tandem seal is the next generation double seal.

The ZMT ZND double/tandem seal is the next generation double seal. The ZMT ZND double/tandem seal is the next generation double seal, because the Inner Cartridge can be changed to do the following:

The ZMT ZND double/tandem seal is the next generation double seal, because the Inner Cartridge can be changed to do the following: