Sanitary Pump Seals

Alfa-Laval Seals

APV Seals

Fristam® Seals

Tri-Clover® Seals

Waukesha® Seals

Sanitary Mixer Seals

ZN Sgl Cartridge Seal

ANSI Process Pump Seals

ZA Sgl Cartridge Seal

ZN Sgl Cartridge Seal

ZND Dbl Cartridge Seal

Process Mixer Seals

ZN Sgl Cartridge Seal

Seal Application Sheet

Sanitary PD Pumps

ZD-U1

ZD Evolution

Sanitary Centrifugal Pumps

ZC-10 Series

Tri-Clover® C-Series

ZMT T3EH & T4EH Series

PD Pump Application Sheet

Tri-Clover ® Pump Parts

C-Series

3EH & 4EH-Series

Waukesha® Pump Parts

Model U1

Model U2

5000 Industrial Series

Waukesha® Pump Repair

Model U1

Model U2

5000 Industrial Series

Fillers

Aseptic Fillers

Automated Aseptic Fillers

Piston Fillers

Vacuum Fillers

Sterilizers

Pasteurizers

Robotic Palletizers

Filler Application Data Sheet

|

||||||||||||||||||||||

|

| ||||||||||||||||||||||

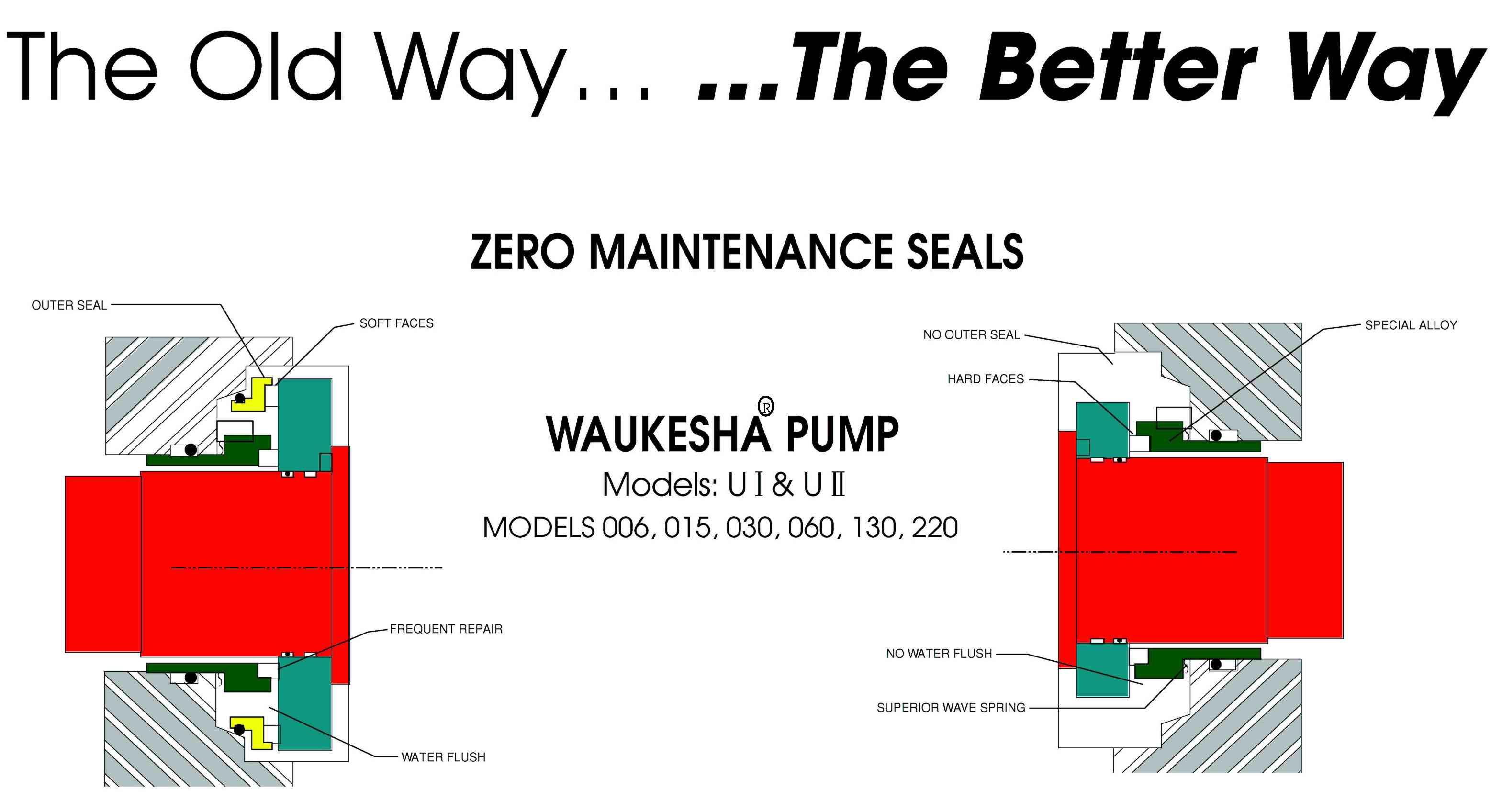

All ZM Technologies'

engineered mechanical seals are waterless (flushless), and are repairable

for a fraction of the price of new.

All ZM Technologies'

engineered mechanical seals are waterless (flushless), and are repairable

for a fraction of the price of new.

Our mechanical seals are easier to install than the OEM, and offer 3-4 times the life of the original seal. | ||||||||||||||||||||||

|

||||||||||||||||||||||

| Waukesha® Pump Seals | ||||||||||||||||||||||

|

||||||||||||||||||||||

|

Click

on image for a larger view |

||||||||||||||||||||||

| 1 | Do you use a double seal for your Waukesha® pumps? |

|||||||||||||||||||||

| 2 | What do you do with your mechanical seals after you remove them from the pump? |

|||||||||||||||||||||

| 3 | Do you like the idea of using water to flush your seals? Please consider the following issues: a) Product contamination. b) Wasting water - one pump will use 1 million gallons of water per year. c) A water flush means you pay for the water twice - first, from the well or city, second, to the sewer. d) Water dumped on the ground may be unsightly and a hazard. |

|||||||||||||||||||||

| 4 | Do you consider production downtime and mechanic time as a part of the total pump maintenance expense? |

|||||||||||||||||||||

| 5 | If our mechanical seal eliminates water consumption and offers 4 - 6 times the seal life, would your TOTAL maintenance expenses be increased or decreased? |

|||||||||||||||||||||

|

||||||||||||||||||||||

Fristam®, Tri-Clover®, and Waukesha® are trademarks of their respective companies.

ZMT, Inc. is not a representative, nor affiliated with Alfa-Laval, APV, Fristam®, Tri-Clover®, or Waukesha®./SPX Flow Technology