Sanitary Pump Seals

Alfa-Laval Seals

APV Seals

Fristam® Seals

Tri-Clover® Seals

Waukesha® Seals

Sanitary Mixer Seals

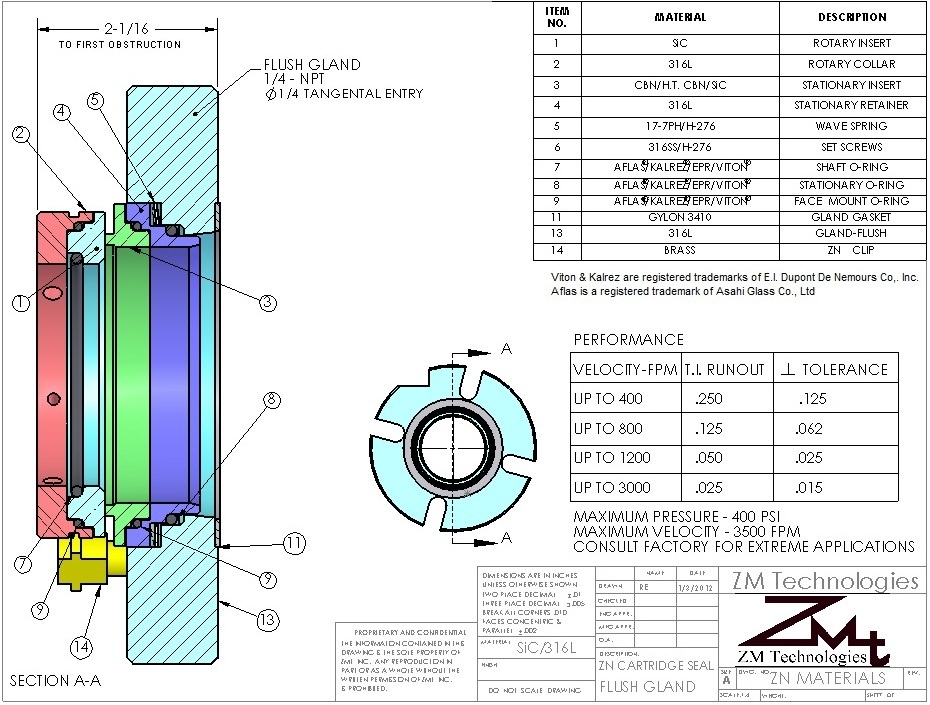

ZN Sgl Cartridge Seal

ANSI Process Pump Seals

ZA Sgl Cartridge Seal

ZN Sgl Cartridge Seal

ZND Dbl Cartridge Seal

Process Mixer Seals

ZN Sgl Cartridge Seal

Seal Application Sheet

Sanitary PD Pumps

ZD-U1

ZD Evolution

Sanitary Centrifugal Pumps

ZC-10 Series

Tri-Clover® C-Series

ZMT T3EH & T4EH Series

PD Pump Application Sheet

Tri-Clover ® Pump Parts

C-Series

3EH & 4EH-Series

Waukesha® Pump Parts

Model U1

Model U2

5000 Industrial Series

Waukesha® Pump Repair

Model U1

Model U2

5000 Industrial Series

Fillers

Aseptic Fillers

Automated Aseptic Fillers

Piston Fillers

Vacuum Fillers

Sterilizers

Pasteurizers

Robotic Palletizers

Filler Application Data Sheet

|

|||||||||||||||||||||

|

| |||||||||||||||||||||

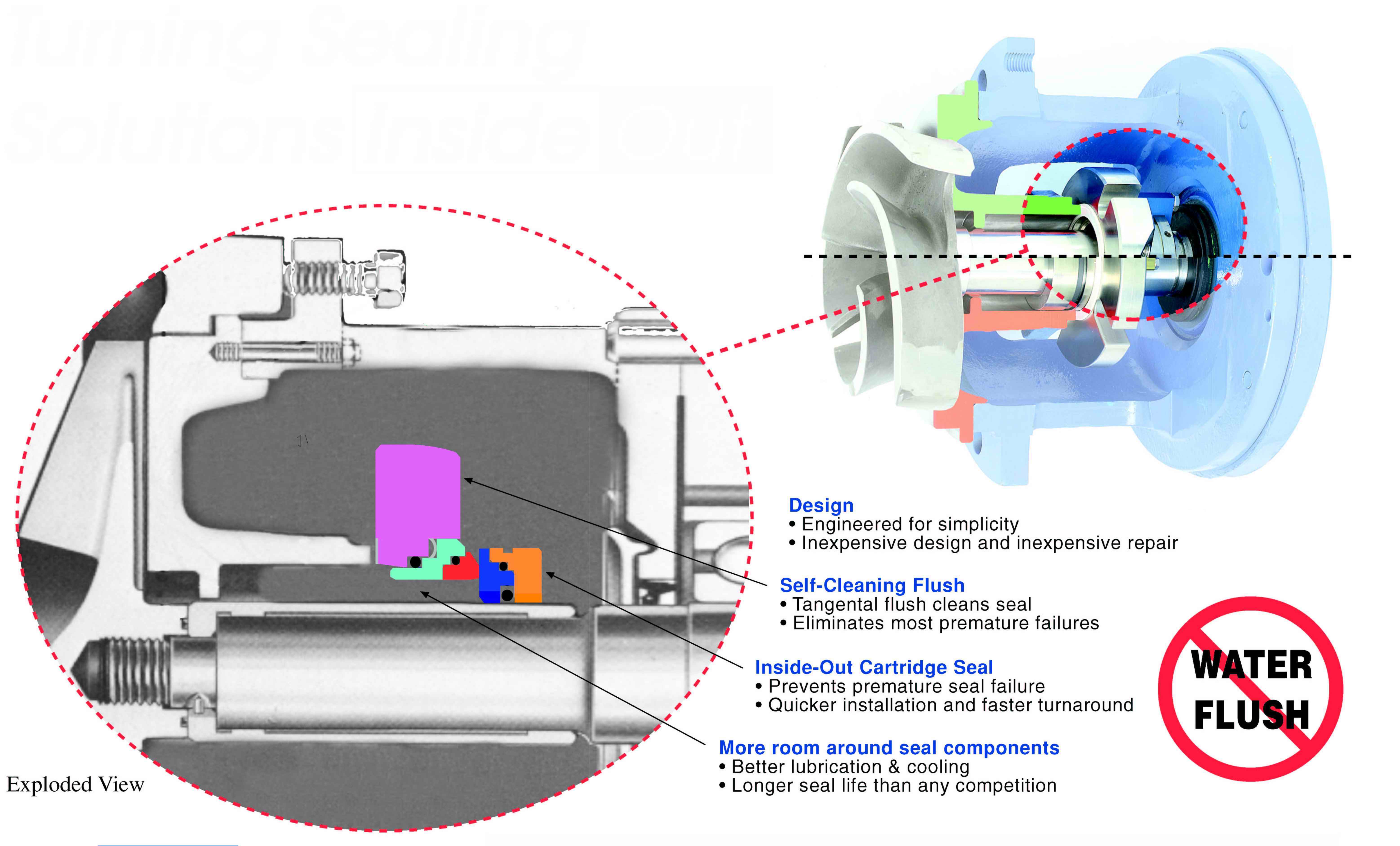

| ZN Pump Seal | |||||||||||||||||||||

|

|||||||||||||||||||||

|

Click

on image for a larger view | |||||||||||||||||||||

|

Questions about the ZMT ZN Pump Seals: | |||||||||||||||||||||

| 1

Does providing a seal with 6X more room for cooling and lubrication improve seal life? | |||||||||||||||||||||

| 2

Since most seals have a 1/32" pathway between the seal faces and the pump stuffing box, which size pathway would provide the most lubrication to the seal face, a 1/32" pathway or a ¼" pathway? | |||||||||||||||||||||

| 3

What would better lubrication do to your seal life? | |||||||||||||||||||||

| 4

All the little springs are eliminated, the seal sleeve is eliminated, the seal is re-configured for longer seal life; do all of these features add up to costing you more or lowering your costs? | |||||||||||||||||||||

| The ZN Seal unique features are as follows: |

|||||||||||||||||||||

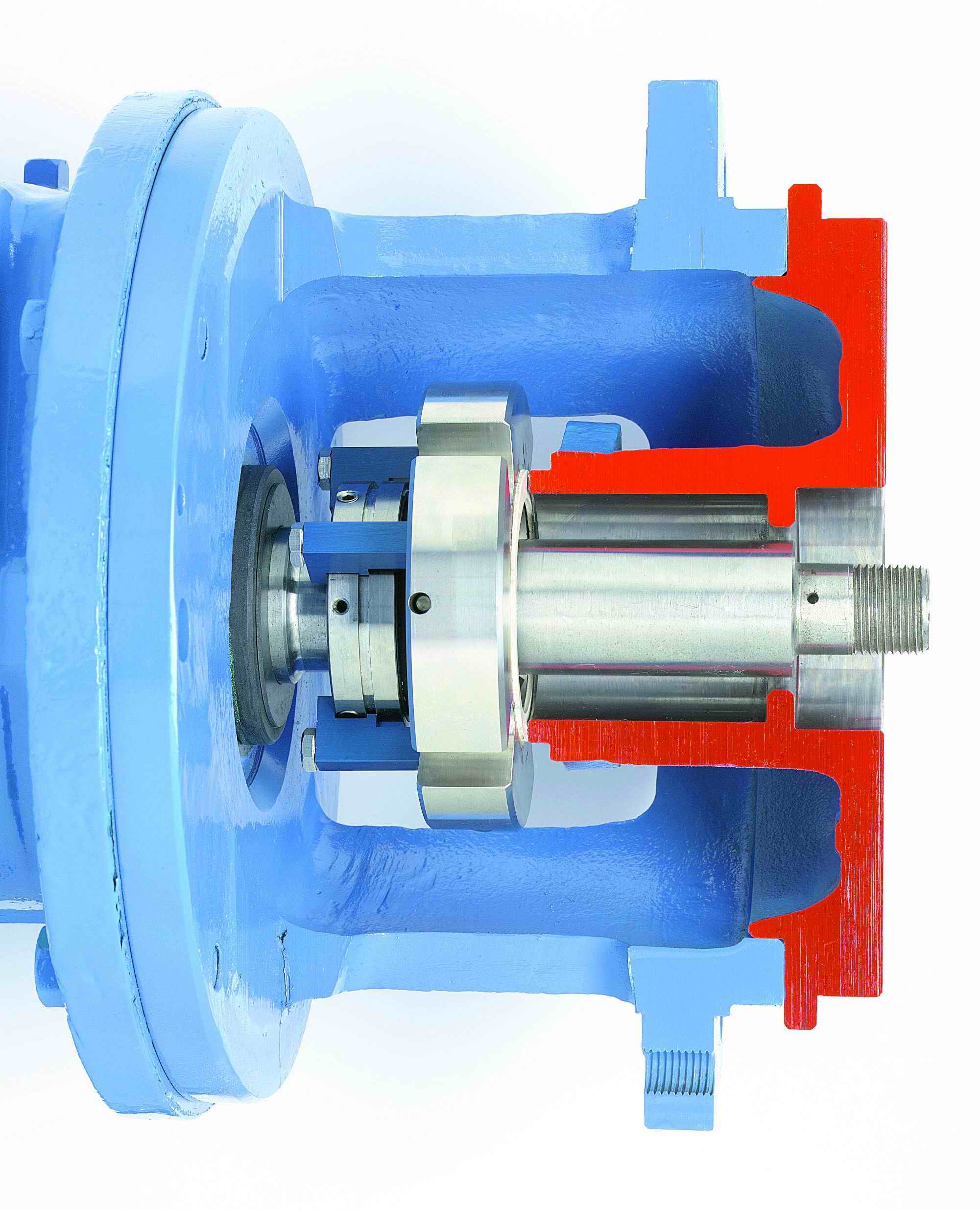

| Seal is bolted OUTSIDE the stuffing box, unlike other seals that are installed inside of the stuffing box. Larger clearances benefit you by better lubrication and better

cooling, which equals longer life. |

|||||||||||||||||||||

| The seal design is simple in concept and simple to manufacture. The result is a seal that is inexpensive to buy and repair. |

|||||||||||||||||||||

|

The ZN seal comes standard with a flushed gland. ZMT recommends, but does NOT require, a bypass flush to the pump discharge or suction. This standard feature gives the customer flexibility to use or not use a flush. The ZN seal can easily be configured with a sleeve and/or a plain gland for many different applications (i.e. - vertical pumps, mixers). Standard pump stuffing boxes have little room for seals - as a result a seal runs HOT. Remember . . . . . . . Heat Kills. Applications: Hot oil, sugar, caustics, slurry, effluent sludge.

|

| Click

on image for a larger view |

|||||||||||||||||||

|

|||||||||||||||||||||

| |

|||||||||||||||||||||

Fristam®, Tri-Clover®, and Waukesha® are trademarks of their respective companies.

ZMT, Inc. is not a representative, nor affiliated with Alfa-Laval, APV, Fristam®, Tri-Clover®, or Waukesha®./SPX Flow Technology